We have gone through multiple rounds of iterations on the Face Shield design, and finally these face shields are ready for you! With comfort in mind, we have designed one of the most lightweight face shields in the market, tested by our very own team. Click here to purchase a set of these face shields for your family and co-workers!

DESIGN CASE STUDY

Ever since embarking on making DIY face shields since the start of the MCO, we have come a long way and learnt a lot from our ‘effort partners’ and everyone around us.

Sewing with the Ongs.

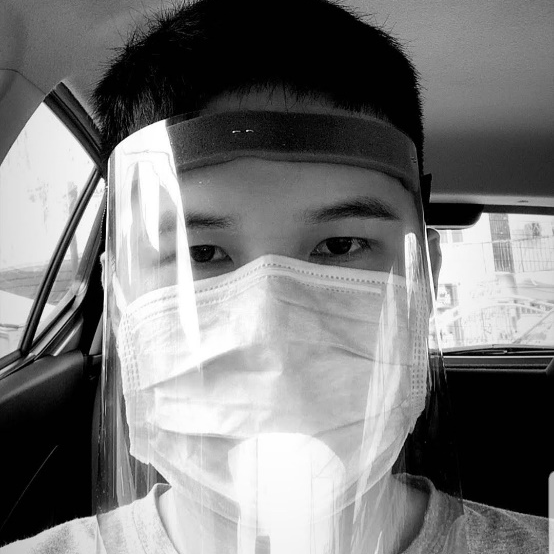

Delivering face shields during MCO.

Material sourcing

The DIY face shield came about at a time when material was scarce (during MCO), we had limited resources and we wanted to have mass deployment to give the most impact. We secured foam by driving off to industrial areas in Balakong, secure elastic bands from our friends at Me.reka and a huge donation, and also secured A4 transparent sheets from a friend we met along the way.

Stuffing our ride with foam.

Double sided adhesive.

To put the foam together, we have tried various methods… from double sided tapes to general adhesives. We have even stapled the foam directly to the transparent sheets but was given discouraging feedback, not because of its danger (we stapled it from the inside). The foam with staples formed an indent on the foam when worn, and this was not preferred by doctors as it allowed gaps on the forehead.

Assembling the foam required a relatively long and laborious process. It involved either stripping the double sided tape on both sides or applying adhesive on the transparent sheet, depending on the method used. Then there was the stapling of the strap onto the sheets.

Stapling Elastic Bands.

Completed Unit.

PRODUCT & User CONSIDERATIONs

As PPE face shield quantities slowly stockpiled in our local hospitals, we started looking at improving the process and outcome. Some key points that we took note of were:

Foam - it was the most comfortable choice as it was soft and light against your forehead. Hard plastic ones were sometimes harsh on the forehead without the foam barrier.

Adhesion – sometimes, certain tapes gave way after a long period of time. Water based adhesive required long drying time.

Labour - process was very slow with many steps of assembly .

Weight – how do we make it weigh next to nothing just like the foam ones. Every gram counts when worn for the whole day.

Sustainability and Recyclability - we really had to try to make a reusable face shield instead of the one time use that will end up in landfill. Material recyclability was also important.

Disinfecting – for it to be reusable, it needed to be easily disinfected with common disinfectant.

Industry partners tried using multiple layers of foam on hard shields.

Using foam on 3D printed shields.

MANUFACTURING CONSIDERATIONS

We seriously considered investing in an injection molded face shield as our molders gave us a really good price of RM20k for the mold. We jumped at it and got our CAD all done up but we just couldn’t convince ourselves to pull the trigger. Was it the perfect solution? Would the ROI be enough? How could we solve the comfort and weight issue? At the same time, we have been noticing the scenes online around the world. We were very inspired by the MIT flat sheet face shield and we decided to switch from a molded part to using a single flat sheet of transparent material.

We started with the simplest components, a face shield and a band that wraps around your forehead. We kept everything minimal, no point over-complicating the whole thing. We kept the design to straight lines without curves to minimize wastage of material. We designed a simple band that would be secured to the face shield quite permanently without relying on any elastic. We then calculated square footage to maximise the use of the material. But things don’t always turn out the way you want it to. Rolled material had edges that can’t be used. So we recalculated and readjusted the dimensions again so that we have as little wastage as possible.

Buckling on the edge.

Wave of destruction (to our material).

OUTCOME

The outcome consists of 3 components: a face shield, a headband and an elastic strap. It is extremely light and comfortable as the headband will form and wrap around your forehead, this is the similar feeling of foam on your forehead. There are no other buttons or plastic parts that comes in contact with the wearer. It comes packed in a flat form, hence saving a lot of postage hassle. It is made from PET, the same material bottles are made from which makes it easily recyclable. The whole shield can be thrown into a pail of disinfectant solution and then hung to dry for use the next day.

Economic Impact

The COVID 19 pandemic impacted small businesses and SMEs tremendously, some at the verge of closing down due to the sudden halt in businesses. However, with projects like these, we partnered with local suppliers and able to reactivate their production pipeline to meet new product demands, and help generate income and sustain their business during these difficult economic times. By purchasing these face shields, you too are part of the team to keep our local SMEs running.

Product Features

Lightweight

We removed all unnecessary material and used the least amount of material possible. This creates a light weight faceshield and takes up the least space in landfill if ever disposed.

Foam Free

No more sticky sweat soaked foam on your forehead. Without the foam, this also means that it can be easily disinfected as the foam piece usually harbours the most bacteria.

Disinfectant

Friendly

Because of the material properties, this means that you can throw the whole face shield into a bucket of disinfectant if you want or spray the whole thing down.

Sustainable & Reusable

Truly reusable as it can be disinfected, friendly to the environment and easily recyclable.

If you’d like to purchase these Face Shields for your personal use, family or co-workers, WhatsApp us direct

or visit our e-shop below!

*Adult and kid sizes available*

Delivery charges apply base on location